PLC’s – 5 DAYS – IS YOUR MAINTENANCE STAFF MULTI-CRAFTED?

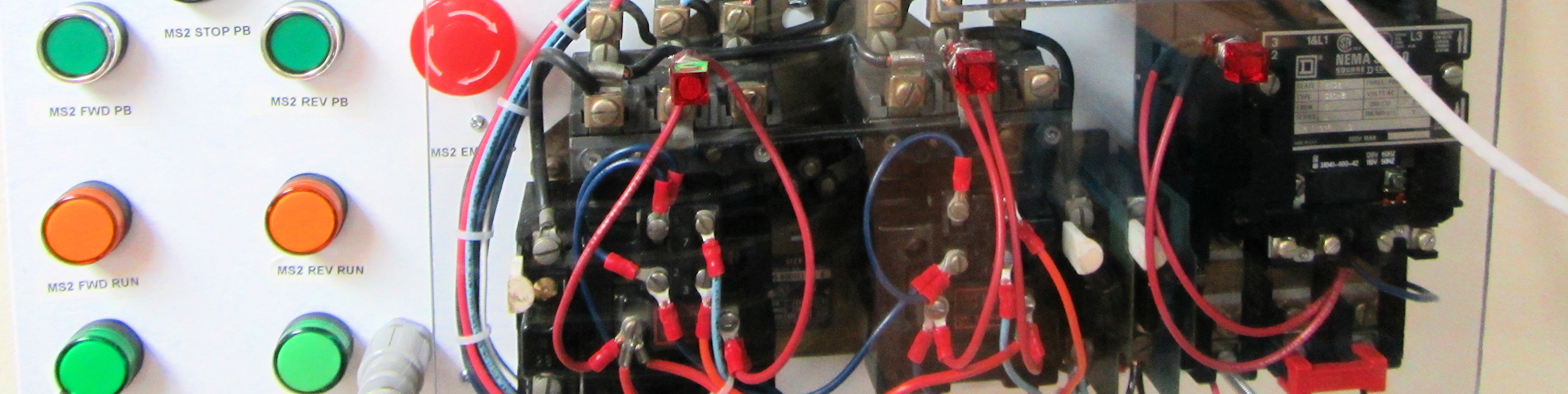

Are they responsible for maintenance, troubleshooting and repair of mechanical, hydraulic and electrical systems? The PLC is or should be the ‘hub’ for troubleshooting any and all nondescript problems. Why? Everything that makes the machine operate can be seen on a PLC program display! Maintenance personnel, including electrical personnel learn to ‘read’ and interpret programmable logic controller programs. The easiest and fastest way to troubleshoot a line down or equipment down situation is by looking at the PLC program. The use of PLC’s in manufacturing facilities is virtually universal. Learning to access the PLC program for the purpose of reading and interpreting PLC programs is not hard to do with proper training.

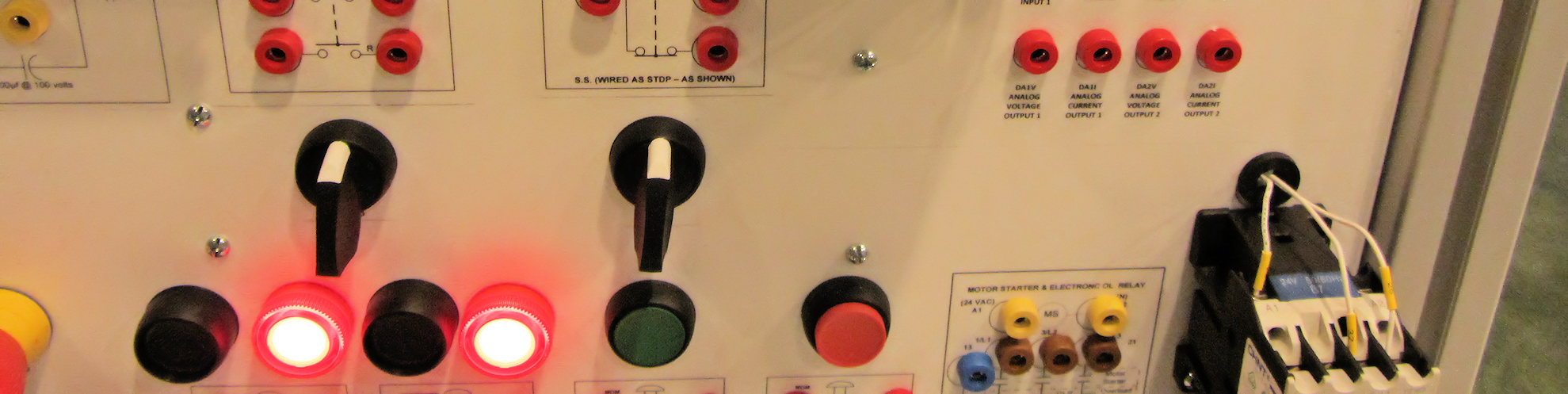

You don’t need to be an electrician either! Learn about input conditioning, analog inputs and outputs that show numerical data like pressure, temperature, level, vacuum, distance and speed. Learn where the numerical data is hidden and how to interpret it. Learn about the use of on delay, off delay and on/off delay functions for proper line and conveyor control. Learn to use counters, LIFO and FIFO stack control. Learn to interpret various math functions and how to “scale” numerical data. Learn to use logical comparisons with numerical data. All of these knowledge “points” are universally used in all PLC programs. The primary purpose of this training course is “reading” and interpreting a PLC program for efficient troubleshooting of a machine or process.

This curriculum and accompanying student workbook was produced by our staff that has worked, installed and programmed PLC’s since their first arrival on the industrial scene and they have worked with this evolving technology ever since.. AMT provides reality-based training with the most popular PLC equipment. The best way to learn to read a PLC program is to program the PLC! Fast paced to keep everyone interested and learning:

A great way to learn programmable logic controllers – Our guarantee – you’ll learn, you’ll like the training or it’s free! Sign up right away – enrollment is limited to a maximum of 12 students.

Prerequisite: Exposure to or working with industrial machinery or processes and working in industrial equipment maintenance – Call us for details.

Click here for a detailed topical outline.

2024 Schedule: Please email enroll@amthydraulics.com to be placed on the course notification list.

Tuition: $1,875.00 includes all training materials, breakfast items, morning and afternoon refreshments, complete lunch and special graduation dinner.

Payment – all major credit cards, cash or company check, PO with 30-day net terms

For more information or check on enrollment availability, call 800-597-6577 or email enroll@amthydraulics.com

Can we help you with your travel arrangements? Ask about AMT’s special hotel rates.

Our pledge for everything we do and all of our courses: Students that successfully complete our training courses will return to their work place with real skills that they can use and their company needs. We hope you and your company will compare before you choose where you go for training. Compare the instructor staff. Compare the training equipment. Compare the training environment in and out of the classroom. Who can best provide you with the information you need to do your job?